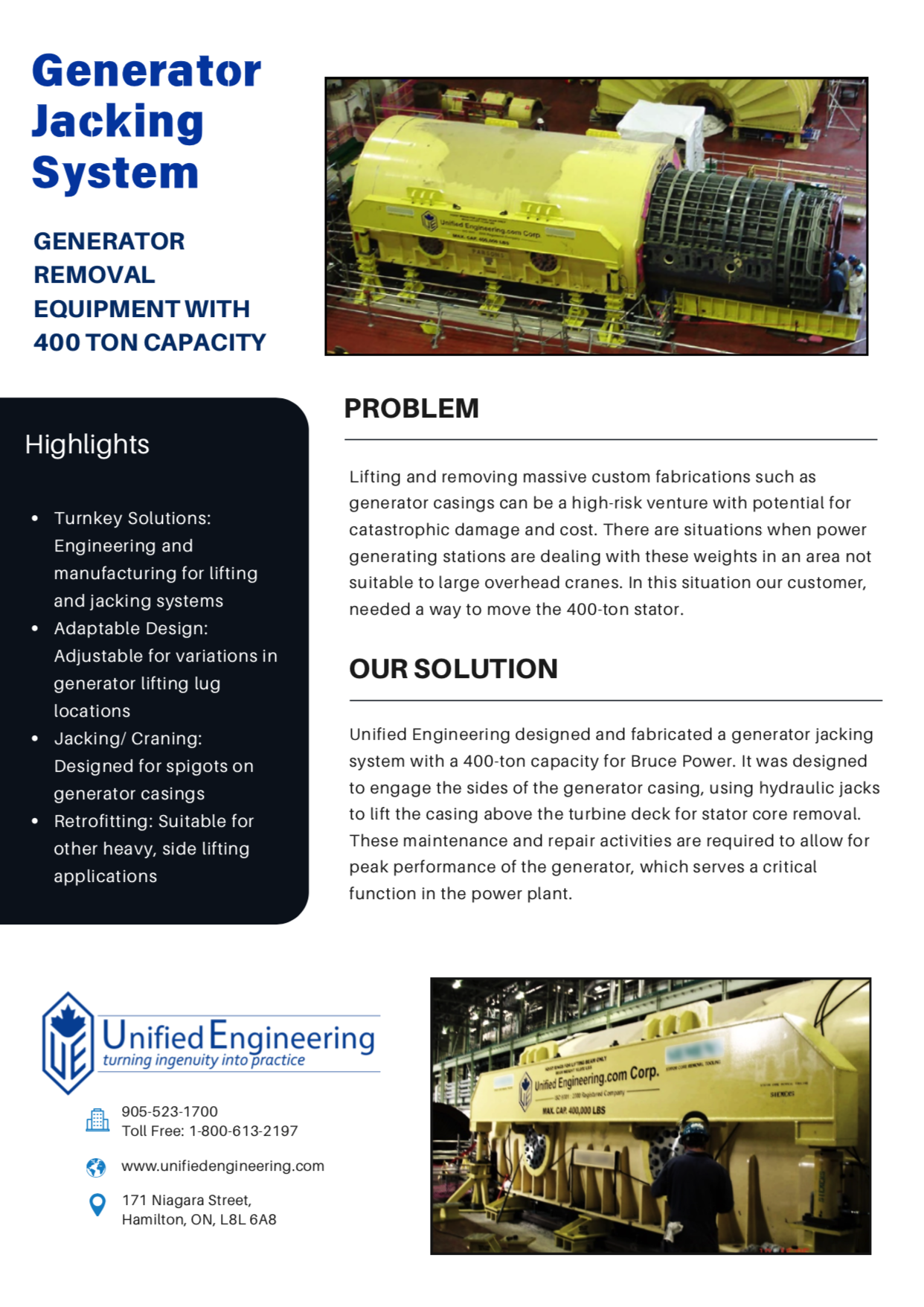

Generator Removal Equipment With 400 Ton Capacity

Lifting massive generator casings in confined or crane-limited environments is a critical yet challenging task in power plant maintenance. Ensuring the safe and efficient handling of these heavy components is essential for maintaining peak generator performance and minimizing downtime. This custom-engineered jacking system provides a robust and adaptable solution, combining precision and reliability to address the unique demands of lifting and maintaining generator casings.

The Challenge:

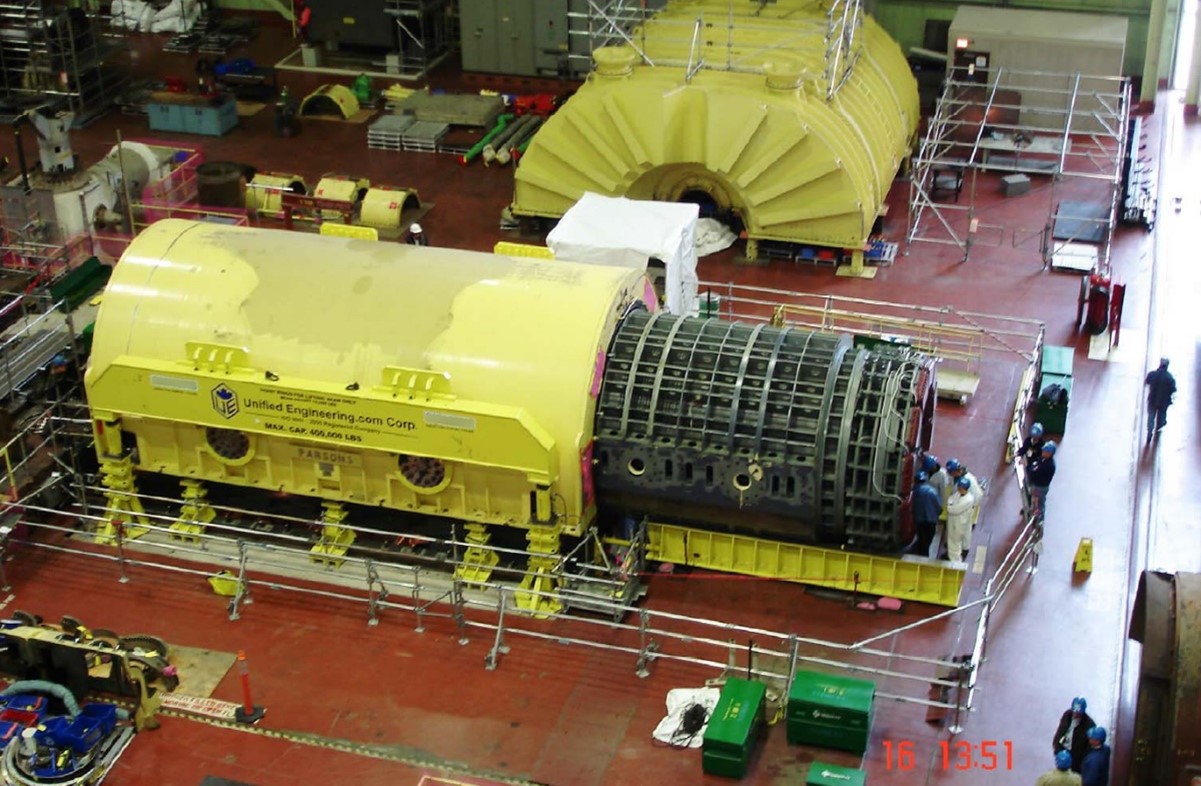

Safely lifting and removing massive fabrications like generator casings presents significant risks, particularly in environments without large overhead cranes. This was the challenge faced by a power plant that needed to perform maintenance on a heavy generator casing. The task required a reliable and precise lifting system capable of incrementally elevating the casing for stator core removal, ensuring safety and stability throughout the process. The absence of suitable lifting infrastructure heightened the complexity, emphasizing the need for a custom solution.

The Solution:

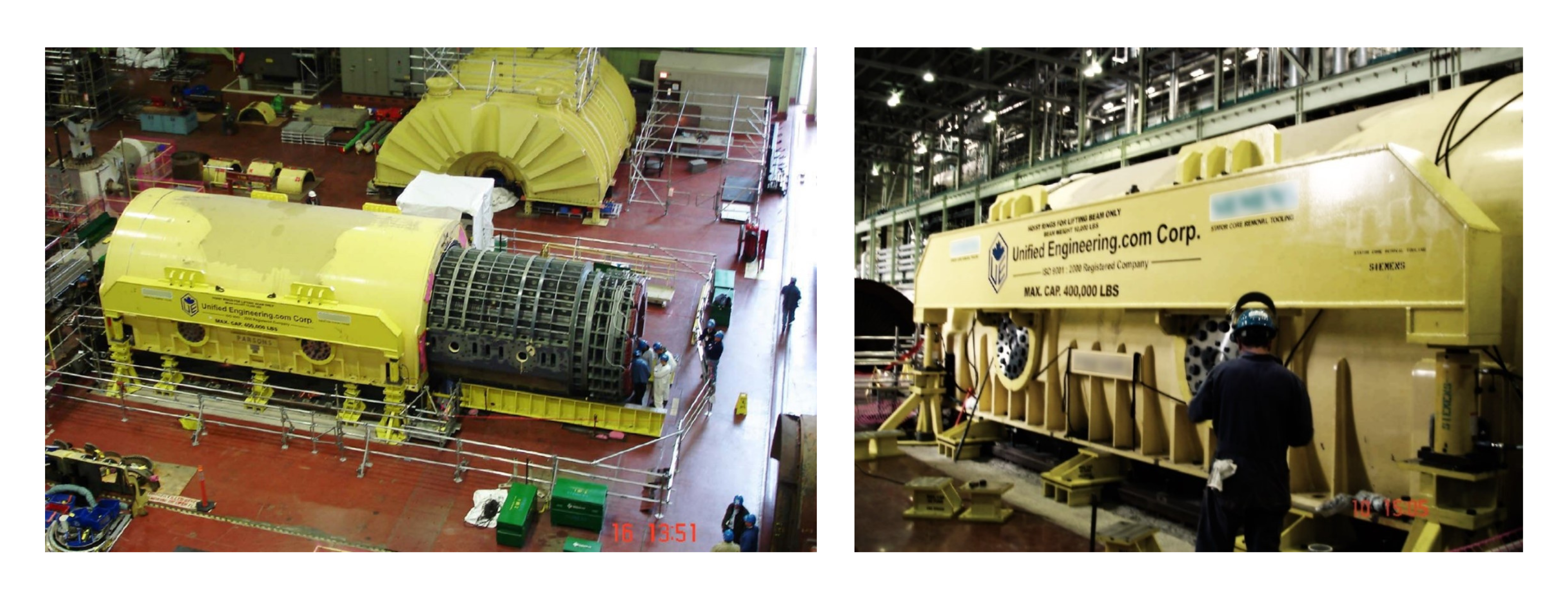

To address this challenge, a 400-ton capacity generator jacking system was designed and fabricated. This system securely engages the sides of the generator casing, enabling hydraulic jacks to lift it incrementally for maintenance. Adjustable lifting yokes along the spreader beam accommodate varying rotor positions, while spigot plates ensure alignment with different lifting lug locations. The system’s design allows the stator core to be safely pushed onto support stools for further work. Built to ASME BTH-1 standards, the system features robust components, including inspection of all welds before and after load testing, ensuring operational reliability.

The Benefit:

The jacking system provides a safe, efficient, and adaptable solution for lifting heavy generator casings. By enabling precise incremental lifting, it minimizes the risk of damage and ensures secure handling during critical maintenance tasks. Its customizable design accommodates various configurations, making it suitable for retrofitting other heavy lifting applications. This innovative system not only supports the maintenance of peak generator performance but also enhances operational safety and flexibility in challenging environments.